What if you could have a machine that could create an infinite (or at least unlimited) improvement in your business? Let’s call it “The Infinite Improvement Machine“. Sounds interesting perhaps? Intriguing even? But perhaps you are feeling a little skeptical?

Now is the time for drastic measures: unprecedented rates of change, highly competitive markets, the whole VUCA meme is enough to keep you awake at night. Thankfully you can read about ISO9000, TQM, six sigma and a dazzling array of quality management and continuous improvement methodologies to help you fall asleep – and fall asleep you will. No-one gets excited about quality management systems, well, almost no-one. They have such a bad image problem that I suspect I’ll even have to promise not to write about them, just to get you to read on to the next paragraph. I’m not letting that cat out of the bag yet, and we haven’t had a PANIC yet.

Let’s deal with your issues with dealing with issues

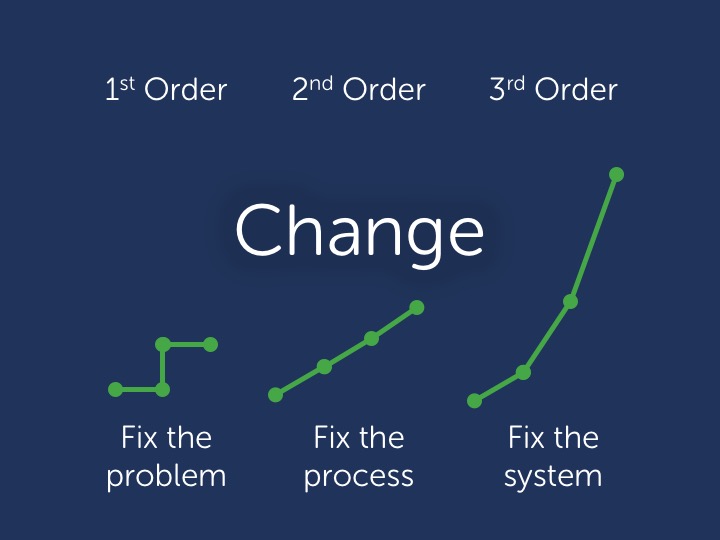

Where do you spend the balance of your time between doing things that were in “the plan” and dealing with things that went wrong? Mistakes happen, problems arise, that is in the nature of things. Hopefully, when things do go wrong, you or your team fix them. Perhaps you give yourself hearty congratulations for fixing the broken thing? Maybe it even stays fixed. Either way it certainly feels like an accomplishment. However the return on that effort is usually exceptionally poor, it is what we call a first order resolution.

What almost anyone from the quality management world will tell you is that you need to improve the process that allowed the issues to happen in the first place. Of course, if you want to improve a process, that does mean that a) you need to have a process and b) you need to have documented the process. Now, I can hear some of you falling asleep already. It takes a particular psyche to want to document a process, and then to follow that documentation, and to be frank that isn’t the kind of psyche found where innovation, knowledge and sophisticated thinking are prized attributes.

Second order resolutions (changing the process that allowed the problem) is hard work, but the results are leveraged. If rather than just rescuing the sale, I improve the sales process, then we win more customers every quarter after that. It’s a good, long-term return, but often “you can’t get there from here” – it isn’t clear how to make that transition in thinking, which is why so many businesses don’t have a robust process for identifying and locking in improvements.

Quality management systems come from third order problem resolution :- the realisation that you need to fix the system that created the process that allowed the problem to happen. What is that system? Its your business – its culture and the people within it. Building the infinite improvement machine is starts from changing people’s mindsets, not from trying to mitigate against their behaviours.

Everybody PANIC!

Every good initiative needs a decent acronym, so here is one for you: P.A.N.I.C.! Please feel free to choose your own, there are plenty, from six sigma’s DMAIC, DMADV and DFSS to Demings’s PDSA/PDCA and Boyd’s OODA. The common theme is a set of elements that create a closed loop between observation and action. I’ve found that PANIC is easy to remember, and a very easy thing to do:

- Plan – define your optimum outcome. Articulate it, and what’s needed to achieve it.

- Act – take action, now.

- Notice – note what happens. Are things going well? Or not well?

- Improve – innovate, improvise, identify what will improve the process and the system.

- Continue – Carry on doing it. Doing the same thing again is how you get good – it’s practice!

Plan the thing, plans are essential. Not those over detailed attempts to match every potential dependency, which never reflect what is or has actually happened. Note what outcome you are trying to achieve, and what you currently believe that you need to get to that outcome. If it is worth doing, and it is going to take more than five minutes of your time, it is worth planning. If nothing else, at least begin with the end in mind.

Act – action, not activity, gets results. Just as it is all too common to find people “too busy to do any planning” it is easy to get too busy with the planning to get to the doing. I once sat in a meeting with a project team that consisted of 7 project managers and one software developer. True story. Don’t be that meeting. Take action, and take action now, even if that is blocking time in the diary for the next step.

Notice – step above the doing to observe what is happening. Demming talks about “Studying” the situation, Boyd about “Observing and orienting” – how do you feel that things are going? How does the team feel that things are doing? What sharable evidence can you see or gather?

Improve – In the education world, you’ll hear about “WWW” & “EBI” – “What worked well?” “Even better if…” – capture feedback that gives opportunities for improvement. Look for improvements at levels 1, 2 and 4: Resolve the problem, improve the process and identify ways to improve the system.

Continue – There is no point in improving your ability to do something you won’t ever do again, after you have done it. Find wants to create repeatability in how things are done. Are there components or processes that you can reuse? Can you make that type of sale again? Can you resolve a problem using a technique that you have already mastered? The Infinite Improvement Machine depends on the outputs being fed back into the input. Or to rephrase and reorder: The most effective inputs for everything that you do come from the outputs of the things you have already done. The most effective things that you do should produce outputs that enable you to do them better next time.

PANIC effectively

The process starts with a mindset change: Noticing. It is what psychologists call “Metacognition” or “thinking about your thinking” – improvement starts with self-awareness. Somewhat ironically that involves getting things out of your head, and writing them down. Metacognition is hard work, and trust me when I say you don’t want to get into the messy area of trying to think about your thinking about how you think. Write down your thoughts, then look at them. Write down your plan, then look at it. Effective PANIC involves moving from the subjective world inside your head, to the objective world outside of it, to somewhere it can become a shared experience. Having a PANIC together is good – a PANIC shared is a PANIC improved.

Stop Panicking

A good feedback system creates stability, and hopefully injects some calm into the system. A good feedback system also includes a degree of observation and that can be uncomfortable for people. Few welcome being “on camera” or feeling that they are being observed, but this is often how quality management and feedback systems are introduced. Start “inside out” and encourage people to create and monitor their own feedback – encourage journaling, noting each day what the learning opportunities were and what they have observed themselves. Once people are comfortable with that, encourage them to share the learning with other people, and start to build a culture that understands and values feedback and continuous improvement. Choose whichever acronym works for you, but establish the habit of reflexivity: people control processes and processes affect people. After every event take a moment to reflect, and capture, opportunities for improvement.